Green fabrication of polyamide nanofiltration membranes with ultra-low chemical consumption by vacuum filtration-spraying assisted interfacial polymerization

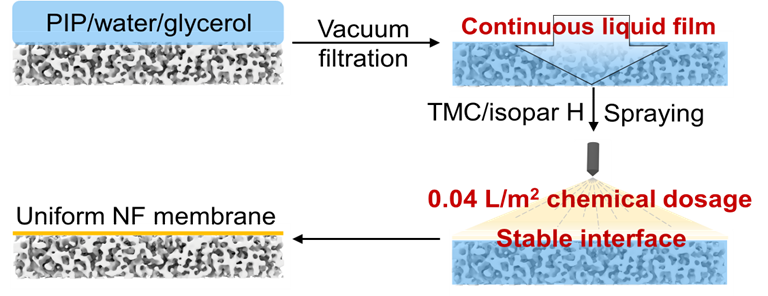

Polyamide nanofiltration membranes, due to their exceptional advantages of high separation efficiency and low energy consumption, have been widely used for hardwater softening, wastewater treatment and brackish water desalination. Despite extensive progress, the conventional fabrication process of polyamide membranes suffers from high chemical consumption (e.g., organic solvent), thus posing a tough challenge in how to harness the minimized chemical dosage for manufacturing intact polyamide membranes. Herein, we report a facile and green strategy to fabricate high-performance polyamide nanofiltration membranes with ultra-low organic solvent consumption, by virtue of vacuum filtration-spraying assisted interfacial polymerization (VSAIP) of piperazine and trimesoyl chloride. With this VSAIP method, uniform and intact polyamide membranes can be fabricated even under an ultra-low organic solvent dosage of 0.0398 L/m2, saving about 95 % organic solvent consumption compared with conventional methods. The results of SEM and AFM images and XPS spectra reveal that the VSAIP-enabled membranes show comparable morphologies and thickness as well as unaltered chemical composition. We further show that the VSAIP method can be applied for high-throughput production of polyamide nanofiltration membranes in a diameter of 30 cm, exhibiting excellent salt rejection (RNa2SO4 = 98.1 %) and high water permeance (22.4 L m−1 h−1 bar−1), comparable with the recently reported state-of-the-art nanofiltration membranes. The low organic solvent consumption and outstanding nanofiltration performance make VSAIP promising in green manufacturing of advanced membranes.

.png)