Congratulations to Jun-Ke Pi for their recent publication on J. Membr. Sci.

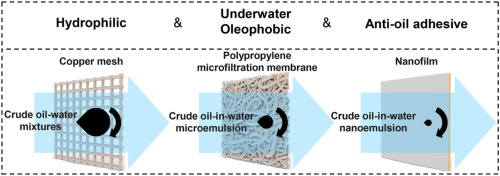

Superhydrophilic filters with excellent subaqueous oil-repellent surfaces are of great significance in the field of crude oil/water separation. Their pore size should be matched with the separation target (smaller than the oil droplets) based on the “size sieving” principle. However, it is a tricky task to facilely and flexibly tune the pore size of filters to effectively separate oily wastewater containing crude oil droplets with different sizes in practice. Herein, a universal platform based on the one-pot mussel-inspiration and silication has been verified to prepare free-standing nanofilms at the air/water interface and deposited coatings on the polypropylene microfiltration membrane or the copper mesh simultaneously. The evolution of chemistries and morphologies of the free-standing films and the deposited coatings is in real-time monitored to deeply understand the formation of the surfaces. We suggest the mussel-inspiration and the silication is asynchronous, being responsible for the formation of the nanofilm and coating surfaces with tunable hydrophilic moieties and micro-nano composite structures. These structure characteristics endow the surfaces with a superhydrophilicity/superoleophobicity underwater and with a low crude oil adhesion especially in basic aqueous environment or salty water regardless of the salt type. The free-standing nanofilms with nano-sized intervals are able to reject nano-droplets from the crude oil-in-water nanoemulsions. The coated polypropylene microfiltration membrane and copper mesh can be applied in oil-in-water microemulsions and oil/water mixtures separation, respectively. All filters show a highly efficient oil repellence of crude oil (>99%) during the separation. This work contributes a promising concept of a one-pot fabrication methodology for fulfilling task-specific requirements of crude oil/water separation.

.png)